Iimveliso

I-MH1515-09 2.6 ukuya kwi-6.2GHz Microstrip Circulator

Imizekelo yoMyalelo we-Microstrip Circulator oyi-2.6 ukuya kwi-6.2GHz

Iinkcukacha eziSiseko zeMicrostrip Cirulator eziyi-2.6 ukuya kwi-6.2GHz

| Ukunganyamezelani | 50 Ω |

| Uhlobo loQhagamshelo | Umcu omncinci |

| Ubungakanani(mm) | 15.0*15.0*4.5 |

| Ubushushu bokusebenza | -55~+85℃ |

Iinkcukacha ze-Microstrip Cirulator eziyi-2.6 ukuya kwi-6.2GHz

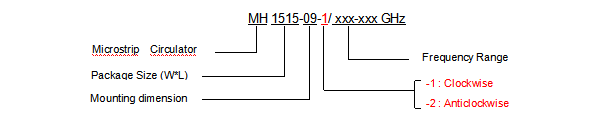

| Inombolo yoMzekelo (X=1: →Ngokuhamba ngewotshi) (X=2: ←Ngokuchasene newotshi) | Uluhlu lweeFreq. I-GHz | IL. i-dB (ubuninzi) | Ukubekwa wedwa i-dB (umzuzu) | I-VSWR (ubuninzi) | Amandla Okuya Phambili CW |

| MH1515-09-X/2.6-6.2GHz | 2.6-6.2 | 0.8 | 14 | 1.45 | 40 |

Imiyalelo:

Inye: Iimeko zokugcina ixesha elide ze-microstrip circulator:

1, Uluhlu lobushushu: +15℃~+25℃

2, Ubushushu obuhambelanayo: 25% ~ 60%

3, Akufanele igcinwe ecaleni kweendawo ezinamandla zemagnethi okanye izinto ze-ferromagnetic. Kwaye umgama okhuselekileyo phakathi kweemveliso kufuneka ugcinwe:

Ii-microstrip circulators ezineefrikhwensi ezingaphezulu kwe-X-band kufuneka zahlulwe ngaphezulu kwe-3mm

Ixesha lokufumana phakathi kwee-circulator ze-C-band microstrip lingaphezulu kwe-8mm

Ezimbini: Ii-microstrip circulators ezingaphantsi kwe-C-band frequency kufuneka zahlulwe ngaphezulu kwe-15mm

2. Jonga le migaqo ilandelayo ekukhetheni ii-microstrip circulators:

1. Xa kususwa kwaye kudityaniswa iisekethe, ii-microstrip isolators zinokukhethwa; I-microstrip circulator ingasetyenziswa xa idlala indima ye-duplex okanye yesangqa kwisekethe

2. Khetha uhlobo lwe-microstrip circulator oluhambelanayo ngokoluhlu lweefrikhwensi, ubungakanani bofakelo kunye nesikhokelo sothumelo esisetyenzisiweyo.

3, xa i-frequency yokusebenza yeesayizi ezimbini zee-microstrip circulators inokuhlangabezana neemfuno zewaranti, amandla amakhulu ngokubanzi aphezulu.

Isithathu: Okwesithathu, ukufakwa kwe-microstrip circulator

1. Xa usebenzisa i-microstrip circulator, isekethe ye-microstrip kwizibuko ngalinye akufuneki ibotshelelwe ukuze kuthintelwe umonakalo woomatshini.

2. Ubume bendawo yokufaka xa idibene nezantsi le-microstrip circulator akufuneki bube ngaphezu kwe-0.01mm.

3. I-microstrip circulator efakiweyo akufuneki isuswe. Kucetyiswa ukuba i-microstrip circulator esusiweyo ingasasetyenziswa.

4. Xa usebenzisa izikrufu, umzantsi akufuneki ugqunywe ngezinto ezithambileyo zesiseko ezifana ne-indium okanye i-tin ukuze kuthintelwe ukuguquka kwepleyiti yomzantsi wemveliso okubangela ukuqhekeka kwe-ferrite substrate; Qinisa izikrufu ngokulandelelana kwe-diagonal, i-torque yokufakelwa: 0.05-0.15Nm

5. Xa iglu ifakiwe, ubushushu bokunamathela akufuneki bube ngaphezu kwe-150℃. Xa umsebenzisi eneemfuno ezikhethekileyo (kufuneka aziswe kuqala), ubushushu bokunamathisela akufuneki bube ngaphezu kwe-220℃.

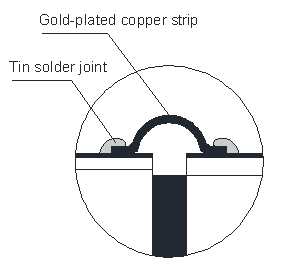

6. Uqhagamshelo lwesekethe ye-microstrip circulator lungaqhagamshelwa ngokuxutywa ngesandla kwe-copper strip okanye i-gold strip/bonding

A. I-welding yebhanti yobhedu enxibelelana ngesandla kwibhanti yobhedu kufuneka ibe yi-Ω bridge, ukuvuza akufuneki kungene kwindawo yokwenza ibhanti yobhedu njengoko kubonisiwe kumfanekiso olandelayo. Ubushushu bomphezulu we-ferrite kufuneka bugcinwe phakathi kwama-60-100℃ ngaphambi kokuwelda.

b, ukusetyenziswa kwebhanti yegolide/uqhagamshelwano lwentambo, ububanzi bebhanti yegolide bungaphantsi kobubanzi besekethe ye-microstrip, akukho nxubelwano oluninzi oluvumelekileyo, umgangatho wenxube kufuneka uhlangabezane neemfuno zendlela ye-GJB548B ka-2017.1 Inqaku 3.1.5, amandla enxube kufuneka ahlangabezane neemfuno zendlela ye-GJB548B ka-2011.1 kunye no-2023.2.

Isine: ukusetyenziswa kwe-microstrip circulator kunye neendlela zokhuseleko

1. Ukucocwa kwesekethe ye-microstrip kuquka ukucoca ngaphambi kokudibanisa isekethe kunye nokucoca indawo yokuwelda emva kokudibanisa i-copper strip. Ukucoca kufuneka kusetyenziswe utywala, i-acetone kunye nezinye izinyibilikisi ezingathathi cala ukucoca i-flux, ukuthintela ukungena kwe-arhente yokucoca kwindawo yokudibanisa phakathi kwemagnethi esisigxina, iphepha le-ceramic kunye ne-substrate yesekethe, okuchaphazela amandla okudibanisa. Xa umsebenzisi eneemfuno ezikhethekileyo, i-flux inokucocwa ngokucoca nge-ultrasonic ngezinyibilikisi ezingathathi cala ezifana notywala kunye namanzi angena-ion, kwaye ubushushu akufuneki budlule kwi-60 ° C kwaye ixesha akufuneki lidlule kwimizuzu engama-30. Emva kokucoca ngamanzi angena-ion, ubushushu kunye nowomileyo, ubushushu abudluli kwi-100℃.

2, kufuneka sinikele ingqalelo ekusebenziseni

a. Ukuba idlula kuluhlu lweefrikhwensi zokusebenza kunye noluhlu lwamaqondo obushushu okusebenza kwemveliso, ukusebenza kwemveliso kuya kuncipha, okanye kungabi nazimpawu zingatshintshiyo.

b. Kucetyiswa ukuba i-microstrip circulator incitshiswe. Amandla okwenyani acetyiswa ukuba abe ngaphantsi kwe-75% yamandla alinganisiweyo.

c. Akufuneki kubekho i-magnetic field enamandla kufutshane nofakelo lwemveliso ukuze kuthintelwe ukuba i-magnetic field enamandla itshintshe i-magnetic field ekhetha imveliso kwaye ibangele utshintsho ekusebenzeni kwemveliso.